Parts & Service

Dyna Crane Services maintains a large inventory of manufacturer specific products and common parts for most OEM applications. With our strong vendor relationships, we can assure our clients the best turn around times on their non-inventory parts and always prioritize their down time situations to restore the equipment safely and reliably back into service.

An example of some of the inventoried parts we stock are:

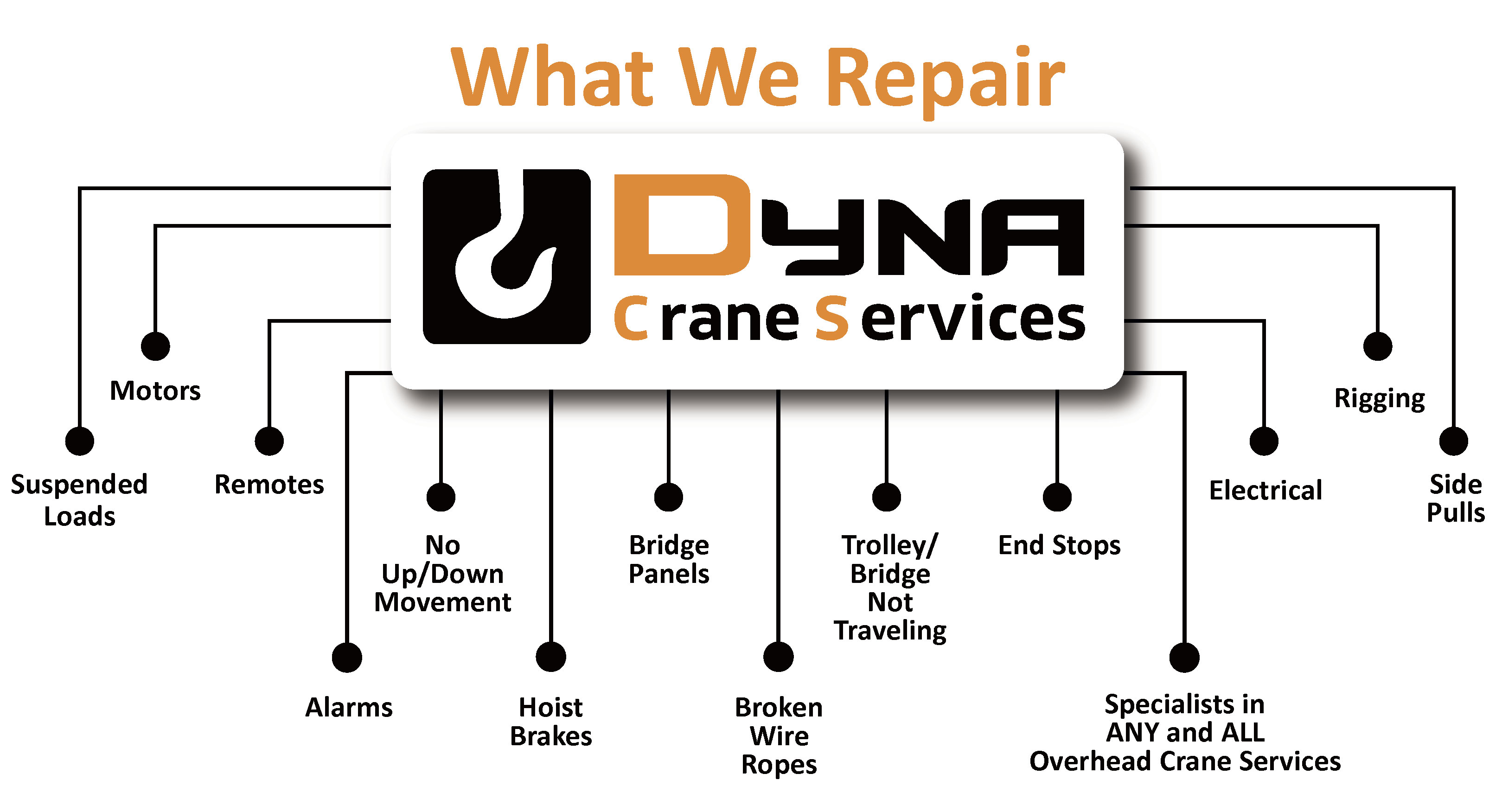

We offer a variety of maintenance and repair services for overhead cranes including:

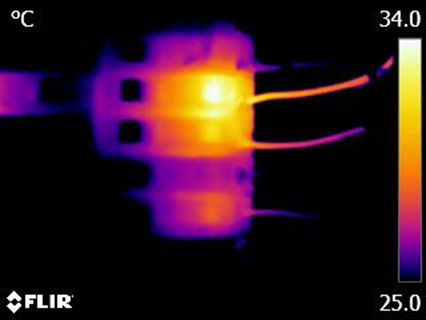

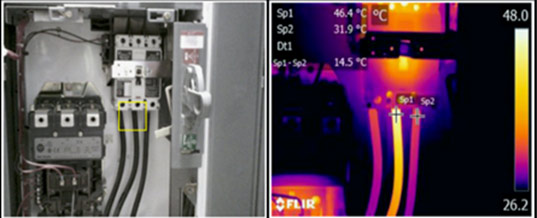

Thermal imaging is the use of an infrared imaging and measurement camera to see and measure thermal energy emitted from an object. Thermal – or infrared energy – is light that is not visible to us because its wavelength is too long to be detected by the human eye. It’s the part of the electromagnetic spectrum that we perceive as heat. In the infrared world everything with a temperature above absolute zero emits heat. Even very cold objects, like ice cubes emit infrared. The higher the objects’ temperature, the great the IR radiation emitted. Infrared thermography cameras produce images of invisible – infrared or “heat” radiation – and provide precise non-contact temperature measurements. Nearly everything gets hot before it has issues that make it fail, making thermal imaging a very valuable diagnostic tool in so many applications.

Dyna Crane Services offers thermal imaging inspections to our clients in addition to our existing preventative maintenance programs. The benefits of thermal imaging are taking preventative maintenance to the next level. Some examples of how thermal imaging can assist are:

Dyna Crane Services has trained and qualified Thermographers. In order to obtain precise measurements and interpret images accurately, Thermography requires an understanding of what the cameras do, how they do it, and why. Some objects may APPEAR to be hotter than others, even if they are actually at the same temperature. Untrained personnel operating this equipment may not interpret images correctly, and therefore misdiagnose systems with a problem that doesn’t exist.

The above picture shows a hot spot at an electrical termination in a breaker panel. This shows there may be corrosion, a poor/weak termination, or degradation in the terminal itself. This is a very basic example and shows the principles behind finding and interpreting the information in the images. This image was taken, tuned and reported by one of our Trained Technicians.

The above picture is an example of what the real image looks like versus the infrared image. This image shows a consistent over amperage of one leg of power feeding a three-phase motor. This unit was noted as 2nd Stage Overheating and was requested by the Thermographer to service at an opportune time, as the motor windings were suspected to be failing. The client went ahead with the further inspection and the windings were confirmed as weak, BEFORE the motor actually failed. The client was able to get a new motor installed prior to failure as a result of this.

Call us today to inquire about Thermal Imaging and its benefits to your company.

Dyna Crane Services offers 24-hour emergency on-call overhead crane services. We know the importance of reliable equipment. If the equipment is down, there is a loss of productive and profitable time. Whether you’ve got a critical lift in the earliest part of the morning or the latest part of the day, call us and we’ll be on site to assist.